CFRP Composite Manufacturing Process – 76 Plastic

76 Plastic is a leading manufacturer and global supplier of CFRP (Carbon Fiber Reinforced Polymer) composites, proudly serving demanding markets such as the EU, USA, Australia, Japan, and Korea. With advanced technology, strict quality standards, and years of expertise, we provide high-performance composite solutions for aerospace, automotive, construction, energy, and sports industries.

What is CFRP Composite?

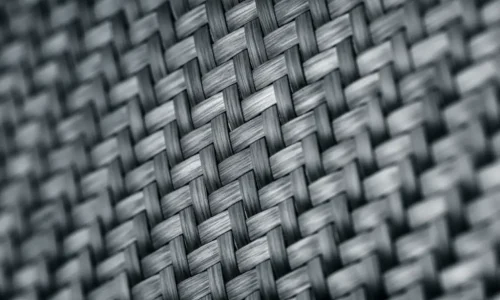

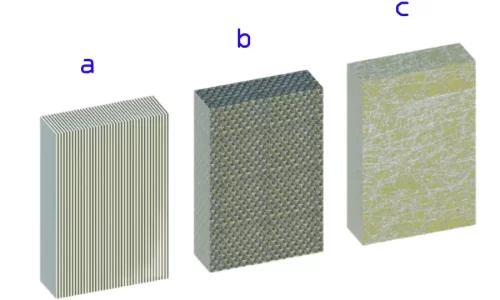

CFRP is a high-strength, lightweight composite material made of carbon fibers (the reinforcement) and a polymer resin matrix (the binder). This combination delivers superior mechanical properties, corrosion resistance, and design flexibility, making CFRP a preferred alternative to metals like steel and aluminum.

CFRP composites are transforming the automotive industry by reducing vehicle weight while maintaining exceptional strength. From chassis and body panels to interior parts, CFRP helps improve fuel efficiency, enhance performance, and increase safety, making it a preferred material for modern and high-performance vehicles. Find more videos about the application process of CFRP composite.

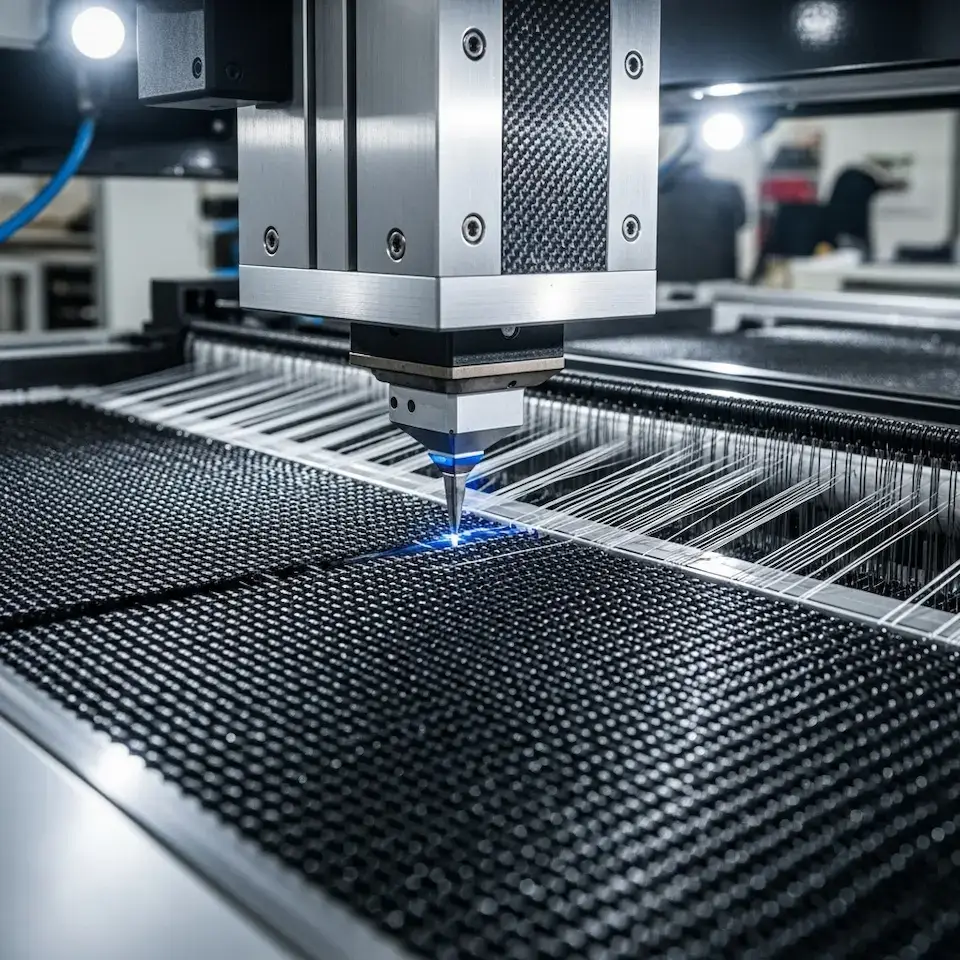

CFRP Manufacturing Process at 76 Plastic

Raw Material Preparation

Premium carbon fibers are sourced and aligned in sheets or fabrics.

Resins such as epoxy, vinyl ester, or polyester are prepared as binding agents.

Lay-up and Pre-preg

Carbon fiber fabrics are layered in specific orientations to optimize strength and stiffness.

In the pre-preg method, fabrics are pre-impregnated with resin and cut into designed shapes.

Molding and Forming

Layers are placed into molds to create components of desired shapes.

Techniques such as Resin Transfer Molding (RTM) or Vacuum Infusion are applied depending on product type.

Curing

Components are cured in an autoclave or oven under heat and pressure.

This step ensures strong bonding between fibers and resin, enhancing durability.

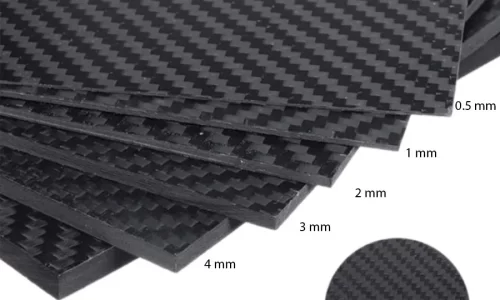

Finishing and Quality Control

Surfaces are trimmed, polished, and inspected.

Each product undergoes rigorous testing for tensile strength, stiffness, and fatigue resistance to meet international standards.

Why Choose 76 Plastic?

Global Reach: Trusted supplier to EU, USA, Australia, Japan, and Korea.

High Standards: Production follows ISO-certified processes with strict quality control.

Customization: Flexible manufacturing to meet industry-specific requirements.

Sustainability: Focus on energy-efficient production and recyclable solutions.

Applications of CFRP from 76 Plastic

Aerospace: Structural components, fuselage, and wings.

Automotive: Chassis, body panels, and performance parts.

Energy: Wind turbine blades, lightweight energy structures.

Sports & Lifestyle: Bicycles, tennis rackets, golf clubs.

No comments.

You can be the first one to leave a comment.