CFRP Composite: A Breakthrough Material for a New Era in Engineering

CFRP Composite (Carbon Fiber Reinforced Polymer) is one of the most advanced and groundbreaking engineering materials of the 21st century. With its ultra-lightweight properties and exceptional strength, CFRP is gradually replacing steel and aluminum, unlocking new opportunities across aerospace, automotive, sports, renewable energy, and more.

What is CFRP Composite? CFRP is a composite material made from two primary components:

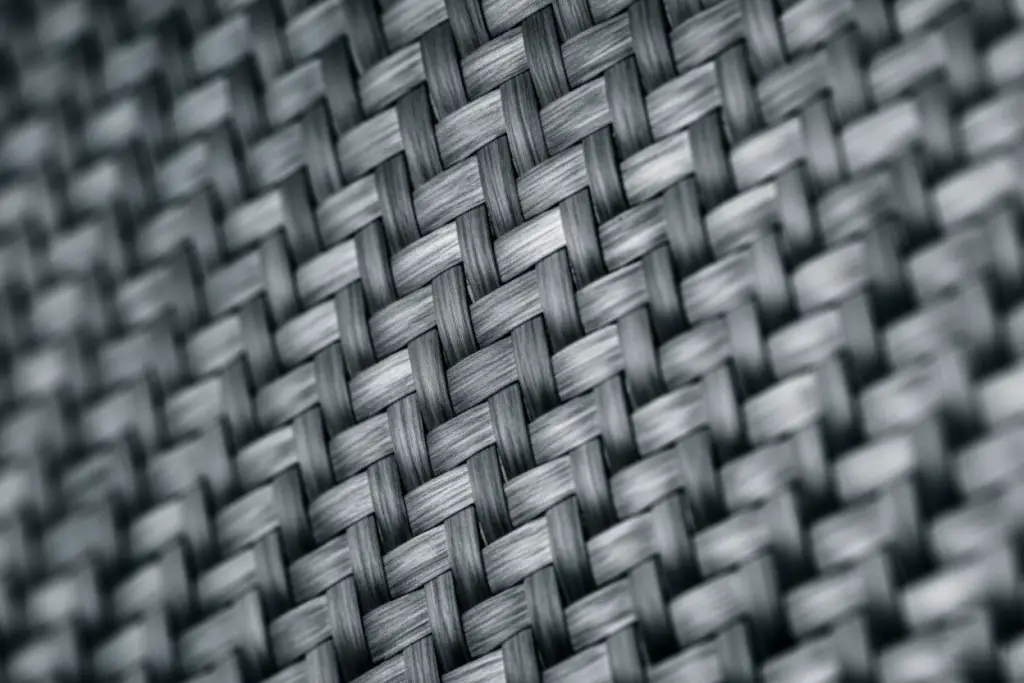

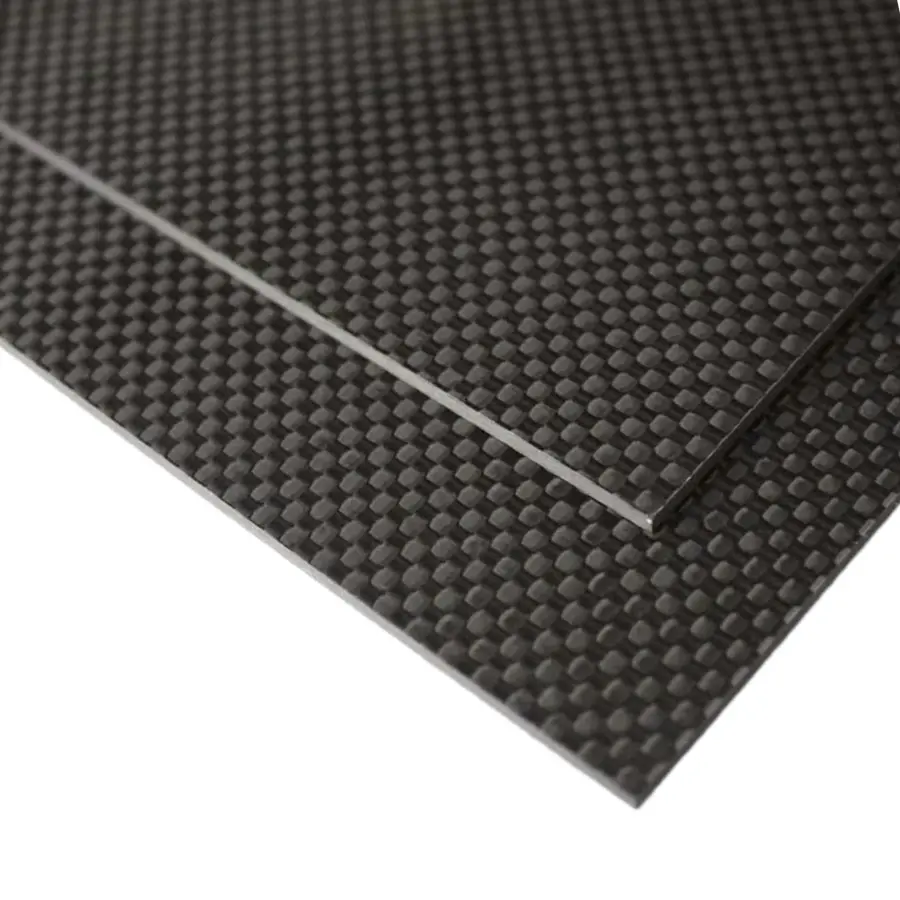

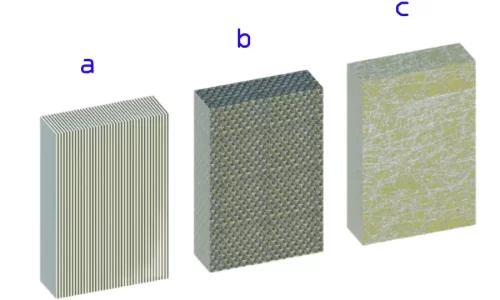

- Carbon Fiber: The reinforcing element, providing superior strength and stiffness. Carbon fibers are thin strands of carbon atoms bonded in a crystalline structure.

- Polymer Matrix: The binding material (Epoxy, Vinyl Ester, or Polyester resin) that encapsulates the carbon fibers, protects them, and distributes load evenly.

Key Properties & Advantages of CFRP

✔️ Ultra-lightweight – 5× lighter than steel and 2× lighter than aluminum, while maintaining higher strength.

✔️ High tensile strength & stiffness – Withstands heavy loads without deformation.

✔️ Corrosion-resistant – Does not rust in moisture, saltwater, or chemicals.

✔️ Excellent fatigue resistance – Withstands repeated stress over time, extending product lifespan.

✔️ Design flexibility – Can be molded into complex shapes, unlike traditional metals.

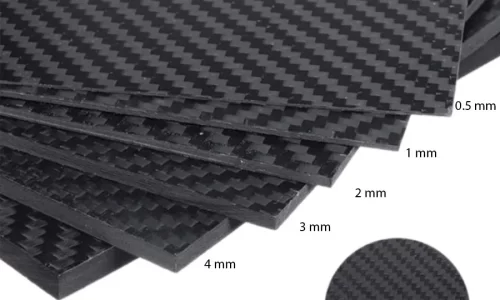

- Pre-preg (Pre-impregnated Method) – Carbon fiber sheets pre-soaked in epoxy resin, layered at different angles, then cured in a high-pressure autoclave. Ideal for aerospace-grade parts.

- Resin Transfer Molding (RTM) – Dry carbon fibers placed in a mold, then injected with resin under pressure. Efficient for mass production of complex shapes.

Applications Across Industries

- Aerospace – Over 50% of Boeing 787 and Airbus A350 structures are CFRP (wings, fuselage, tail), reducing weight and fuel consumption.

- Automotive & Racing – Supercars and Formula 1 use CFRP for chassis, body panels, and interiors to boost speed and safety.

- Sports Equipment – Bicycles, golf clubs, tennis rackets, and fishing rods leverage CFRP for high performance.

- Renewable Energy – Wind turbine blades are longer and lighter with CFRP, producing more power.

- Medical – Used in prosthetics and orthopedic devices thanks to its lightweight strength.

Challenges & Future Outlook

⚠️ High Cost – Carbon fiber production and complex processing remain expensive.

⚠️ Recycling Difficulty – Strong bonding between resin and fibers makes recycling a challenge. 🔬 Research is ongoing to lower costs and develop recycling solutions. With continued innovation, CFRP is shaping the future of engineering toward lighter, more sustainable, and more efficient products.

Contact 76 Plastic Company Name: 76 Plastic

📍 Office & Factory 1: Alley 1, Kieu Ky Street, Gia Lam Commune, Hanoi, Vietnam 10000

🏭 Factory 2: Industrial Cluster, Nhu Quynh Commune, Hung Yen Province, Vietnam 17000

📧 Email: info@76plastic.com.vn

📞 Hotline: +84 243 6789 321

📱 Mobile: Mr. Andy – Project Director: +84 961 160 818

Mrs. Jasmin – International Sales Specialist: +84 962 717 699

🕐 Working Hours:

- Monday – Friday: 7:30 a.m – 4:30 p.m

- Saturday: 7:30 a.m – 11:30 a.m

No comments.

You can be the first one to leave a comment.