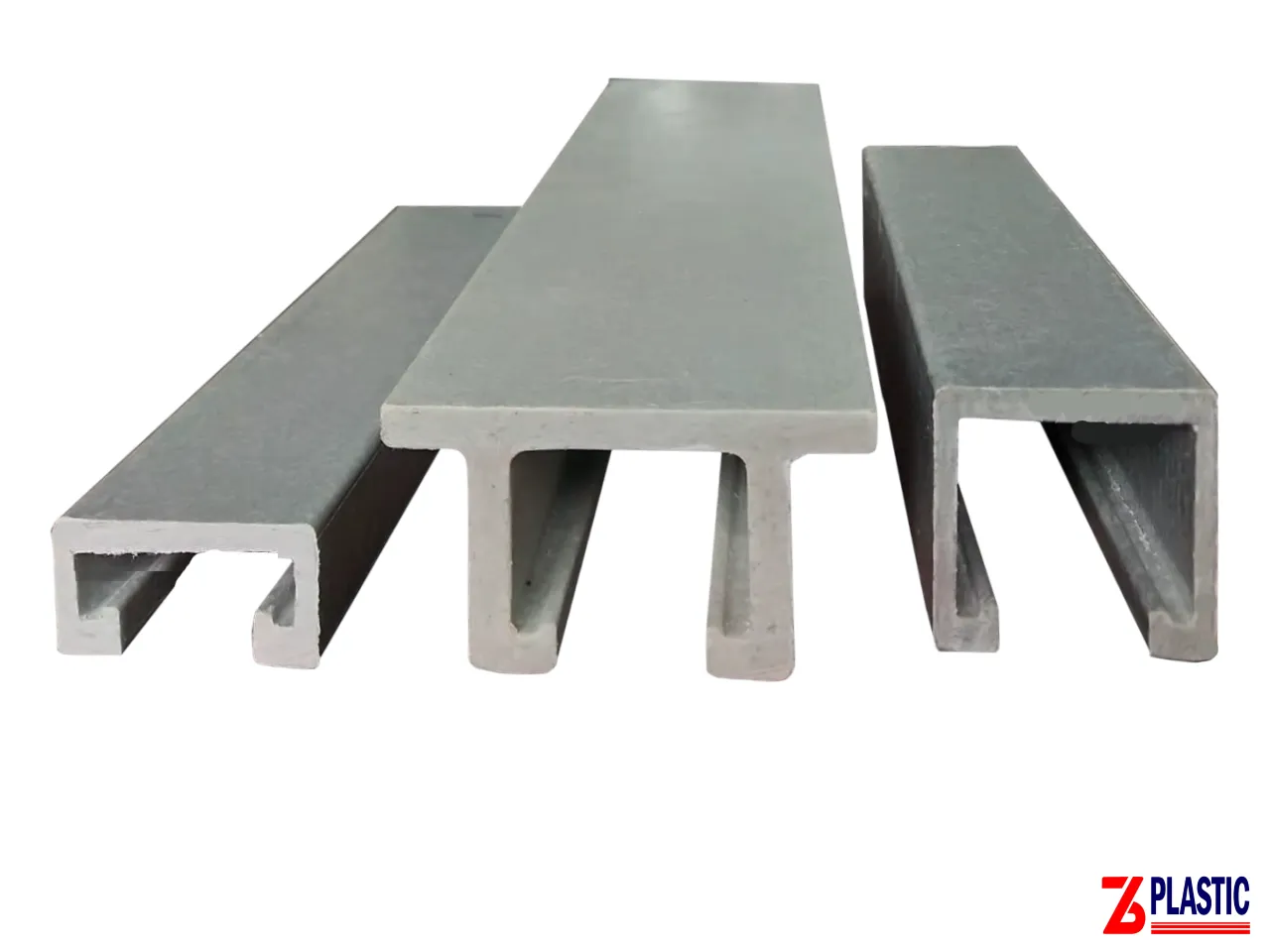

Customized FRP/GFRP Beam – The Smart, Lightweight Structural Solution for Modern Construction

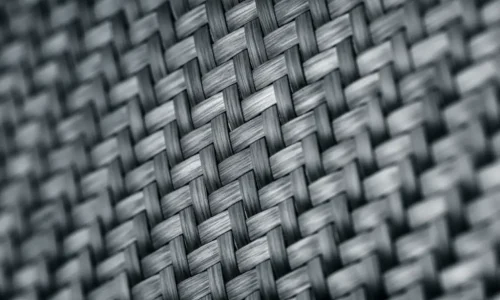

In recent years, Customized FRP/GFRP Beams have become one of the most trusted alternatives to traditional materials like steel, aluminum, and wood. With their exceptional strength, lightweight design, corrosion resistance, and long service life, FRP (Fiberglass Reinforced Polymer) beams are now widely used in construction, marine, energy, and infrastructure projects worldwide.

At 76Plastic, we focus on providing fully customized FRP/GFRP beams based on customer requirements—from dimensions, colors, thickness, and shapes to mechanical performance. Our team ensures that every product meets global standards and performs stably even in the harshest environments.

⭐ What Makes Customized FRP/GFRP Beams Special?

Compared to steel beams, FRP/GFRP beams offer significant advantages:

✔ Lightweight but exceptionally strong: Only 1/4 the weight of steel, but offering high tensile strength. Perfect for buildings where weight reduction is critical.

✔ Corrosion-free and chemical-resistant: FRP beams do not rust or degrade—ideal for coastal areas, wastewater plants, chemical factories, and outdoor structures.

✔ Electrical & thermal insulation: Naturally non-conductive, making FRP beams suitable for electrical projects and high-safety areas.

✔ Long lifespan with minimal maintenance: Once installed, FRP requires very little repair, helping reduce long-term operating costs.

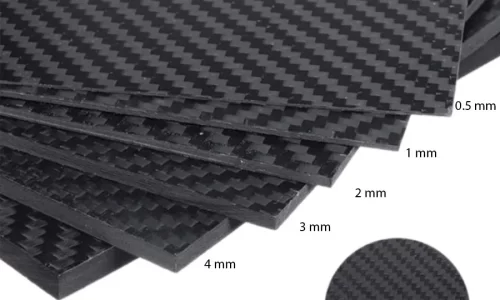

✔ Fully customizable: We manufacture beams based on your exact specs:

Dimensions: Length, width, height tailored to project needs.

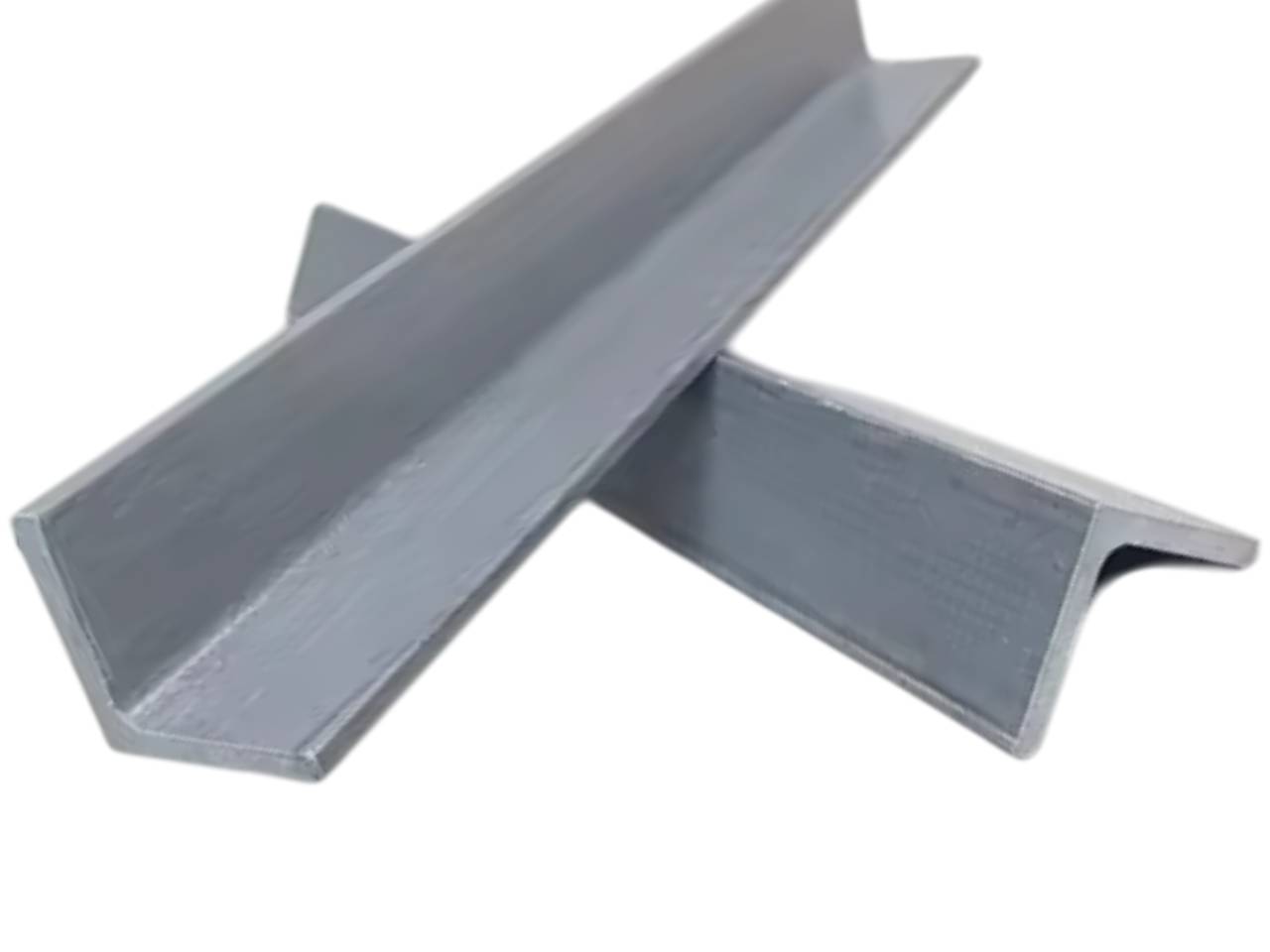

Shape: I-beam, H-beam, U-channel, box beam, round tube.

Performance: Strength class, color, and UV protection options.

👉 Learn more: Explore detailed GFRP material properties here: GFRP Composite Materials

⭐ Applications of Customized FRP/GFRP Beams

With outstanding durability, FRP beams are the go-to solution for:

Construction frameworks & structural supports

Chemical plants & offshore platforms

Bridge walkways and pedestrian platforms

Cable trays & electrical support systems

Cooling towers and rooftop structures

Marine docks & aquaculture systems

They perform especially well in environments where metal rapidly degrades due to moisture, saltwater, or aggressive chemicals.

⭐ Why Choose 76Plastic for Customized FRP/GFRP Beams?

With over 20 years of manufacturing experience, 76Plastic delivers FRP products to more than 120 countries, including the USA, Germany, Canada, Korea, Japan, the UAE, and Saudi Arabia.

We focus on delivering value through:

High–precision customization: Tailored exactly to your drawings.

Stable quality: Consistent performance batch after batch.

Competitive pricing: Direct factory costs.

International export standards: Meeting rigorous global requirements.

Strong production capacity: Ready for bulk and urgent orders.

External Reference: 👉 American Composites Manufacturers Association (ACMA): https://acmanet.org/

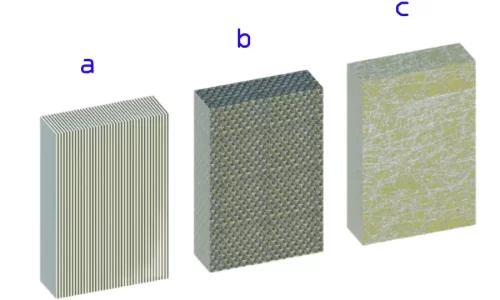

⭐ Suggested Images for Your Project

To help you visualize, here are typical applications (Placeholders):

⭐ Conclusion

Customized FRP/GFRP Beams are becoming an essential structural material for modern engineering thanks to their durability, flexibility, and long-term economic benefits. At 76Plastic, every beam is manufactured with precision, ensuring top performance in even the most demanding applications.

Ready to upgrade your project materials? If you need reliable, customized, and export-standard FRP beams, contact 76Plastic today for a consultation and a competitive quote.

No comments.

You can be the first one to leave a comment.