GFRP Composite Materials: A Comprehensive Overview

Glass Fiber Reinforced Polymer (GFRP) is a high-performance composite material that combines the strength of glass fibers with the flexibility and corrosion resistance of polymer resins. This unique combination results in a lightweight, durable, and versatile material with numerous applications across various industries.

Comparison of Load-Bearing Capacity, Heat Resistance, Impact Resistance, and Fatigue Strength between GFRP and Other Materials

| Property | GFRP | Steel | Aluminum |

|---|---|---|---|

| Load-bearing capacity | Depends on the type of glass fiber and resin. Generally, GFRP has high tensile and compressive strength, especially when compared to its weight. | Very high, especially for high-strength steel. | Relatively high, but lower than steel. |

| Heat resistance | Good, can withstand temperatures up to hundreds of degrees Celsius depending on the type of resin. However, at extremely high temperatures, mechanical properties may degrade. | Good, can withstand high temperatures. | Good, but inferior to steel at high temperatures. |

| Impact resistance | Good, has good ability to absorb impact energy, helping to minimize damage. | Relatively good, but may be permanently deformed after a strong impact. | Good, but inferior to GFRP. |

| Fatigue strength | Good, can withstand repeated loads without a significant reduction in strength. | Good, but may experience fatigue if subjected to varying loads over a long period. | Good, but inferior to GFRP. |

| Specific gravity | Light, about 1/4 to 1/2 the weight of steel. | Heavy. | Lighter than steel but heavier than GFRP. |

Detailed Explanation:

- Load-bearing capacity: GFRP can be designed to achieve tensile and compressive strengths comparable to steel, but with a much lighter weight. This makes GFRP an ideal choice for applications where weight reduction is critical without compromising strength.

- Heat resistance: The heat resistance of GFRP depends on the type of resin used. Epoxy and vinyl ester have better heat resistance than polyester. However, at extremely high temperatures, GFRP may soften or lose its mechanical properties.

- Impact resistance: GFRP has a good ability to absorb impact energy, helping to minimize damage when impacted.

- Fatigue strength: GFRP has high fatigue strength, meaning it can withstand repeated loads over a long period without a significant reduction in strength.

- Specific gravity: GFRP has a much lower specific gravity than steel and aluminum, reducing the weight of the structure and saving transportation costs.

Additional Images:

To further illustrate, you can add the following images to your article:

- A comparison chart of the tensile strength, compressive strength, and modulus of elasticity of GFRP, steel, and aluminum.

- Images of GFRP products used in various applications (e.g., wind turbine blades, boat hulls, wall panels).

- A micrograph of the glass fibers and resin in GFRP composite material.

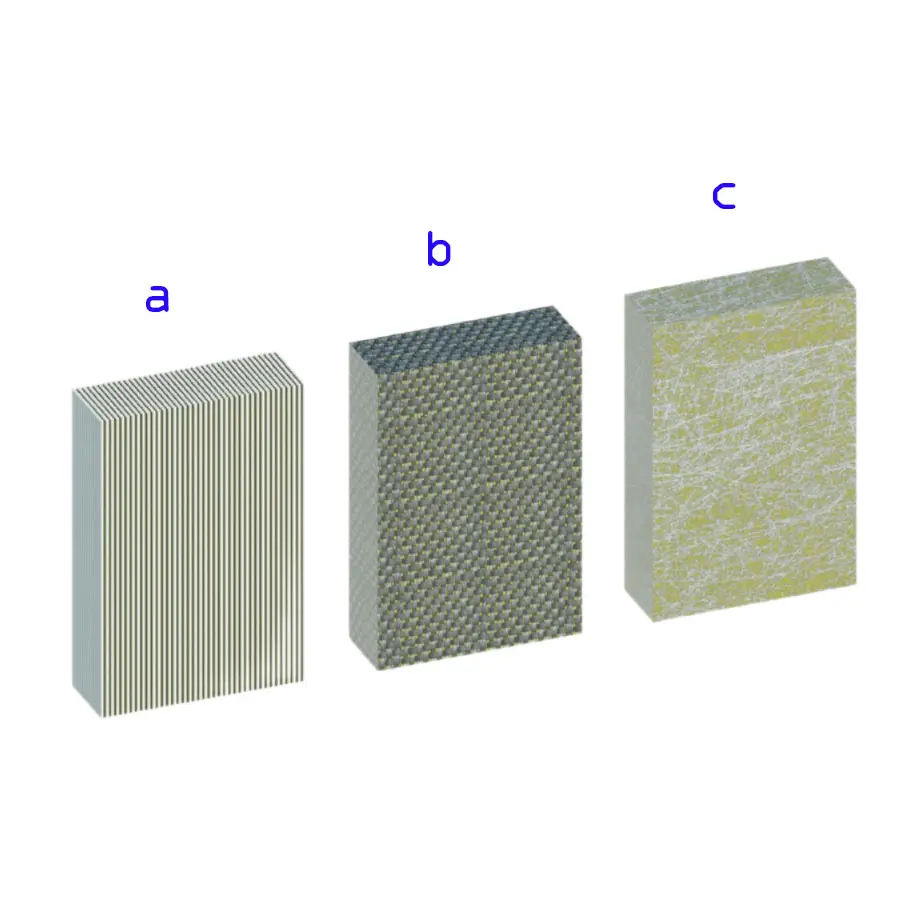

The Structure of GFRP

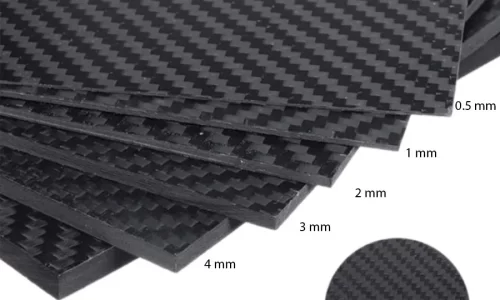

GFRP composites are composed of two primary components:

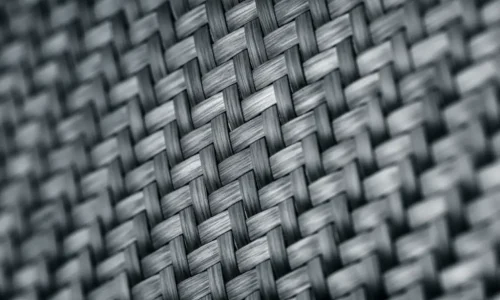

- Glass Fibers: These fibers provide the material’s strength and stiffness. They are woven or chopped into various forms to achieve specific mechanical properties.

- Polymer Resin: The resin matrix binds the glass fibers together, protecting them from environmental factors and providing additional strength.

Advantages of GFRP

- High Strength-to-Weight Ratio: GFRP offers exceptional strength and stiffness while being significantly lighter than traditional materials like steel or aluminum.

- Corrosion Resistance: Resistant to corrosion, making it ideal for harsh environments.

- Design Flexibility: Can be customized into various shapes and sizes to meet specific requirements.

- Durability: Long-lasting performance with minimal maintenance.

- Thermal and Electrical Insulation: Excellent insulator, making it suitable for various applications.

GFRP’s versatility has led to its widespread use in various industries:

- Construction: Structural reinforcements, bridge components, roofing, and cladding.

- Aerospace: Aircraft components, satellite structures, and drone frames.

- Automotive: Vehicle components, body panels, and chassis frames.

- Marine: Boat hulls, masts, and marine equipment.

- Sports and Leisure: Golf clubs, fishing rods, and sports equipment.

- Industrial: Pipes, tanks, and machinery components.

Why Choose GFRP?

GFRP offers a sustainable and cost-effective solution for many industries. By choosing GFRP, you can benefit from:

- Reduced Weight: Lower transportation and installation costs.

- Increased Strength and Durability: Longer lifespan and reduced maintenance.

- Improved Performance: Optimized designs and enhanced functionality.

- Environmental Friendliness: Reduced environmental impact and energy consumption.

Partner with 76Plastic

At 76Plastic, we specialize in providing high-quality GFRP products. Our commitment to excellence and customer satisfaction ensures that you receive the best possible products and services.

Contact us today to learn more about our GFRP solutions.

mail: info@76plastic.com.vn

Phone number

Hotline: +84 243 6789 321

Mobile: Mr. Andy/+84 961 160 818 – Project Director

Fb: 76plastic

No comments.

You can be the first one to leave a comment.