Manufacturers

GFRP is a lightweight, durable,

and corrosion-resistant material

ideal for modern construction and industrial use.

Product Categories

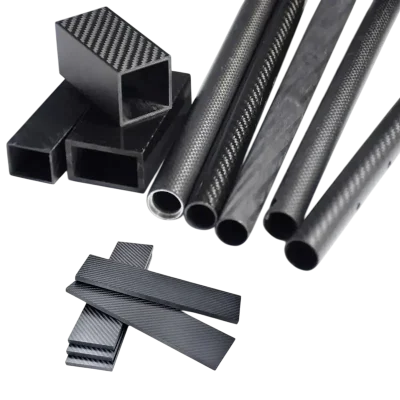

FRP PRODUCTS

Composite materials have high mechanical strength, are resistant to UV rays, are resistant to aging, weather, have outstanding heat and electrical insulation, are extremely resistant to corrosion and chemicals, and have a long service life. Composite materials are 2-3 times superior to metal or wood. With the above outstanding advantages, it can be affirmed that Composite is the best material on the market today. In terms of properties and longevity, Composite is superior to traditional materials.

ABOUT US

76 Plastic Foam Joint Stock Company, formerly known as Plastic Foam Enterprise is headquartered in Duong Xa Commune, Gia Lam District, Hanoi City, Vietnam. Established on May 10, 2004, we have nearly 20 years of experience in the field of plastic and foam products. Our X2 factory is located in Tan Quang Commune, Van Lam District, Hung Yen Province, Vietnam.

76 Plastic Foam Joint Stock Company is an enterprise specializing in manufacturing shaped EPS foam products, FRP products/tubes/profiles/poles, PP woven straps and outdoor products such as camping chairs, camping tables and folding wagons, etc.

OUTDOOR PRODUCTS

76 Plastic Foam Joint Stock Company is a professional OEM company of outdoor products such as folding chairs, folding tables and folding wagons of all kinds. In addition to accurately implementing customer designs, we also proactively invest in R&D to help customers realize product improvement ideas and develop new products.

We, emphasizing quality and credit, provide reliable products at reasonable prices to meet customers′ demands in the spirit of keeping sincere, faithful and diligent.

We chase the perfect of design, procedure and structure of the goods and look it as the guarantee of high quality and high level of the goods.

With complete and modern equipment, we are able to supply 250,000 sets of products annually.

FOAM FACTORY

EPS foam insert is a type of EPS packaging foam made from EPS foam beads shaped by a mold heated to 100 degrees Celsius for the appropriate time to produce a product shaped according to the customer’s design. EPS foam particles containing 98% air on the product have the advantage of damping and impact resistance, suitable for inserting into the packaging stage to protect the product.