Description

Carbon Fiber Reinforced Polymer (CFRP) Laminates: A Comprehensive Guide

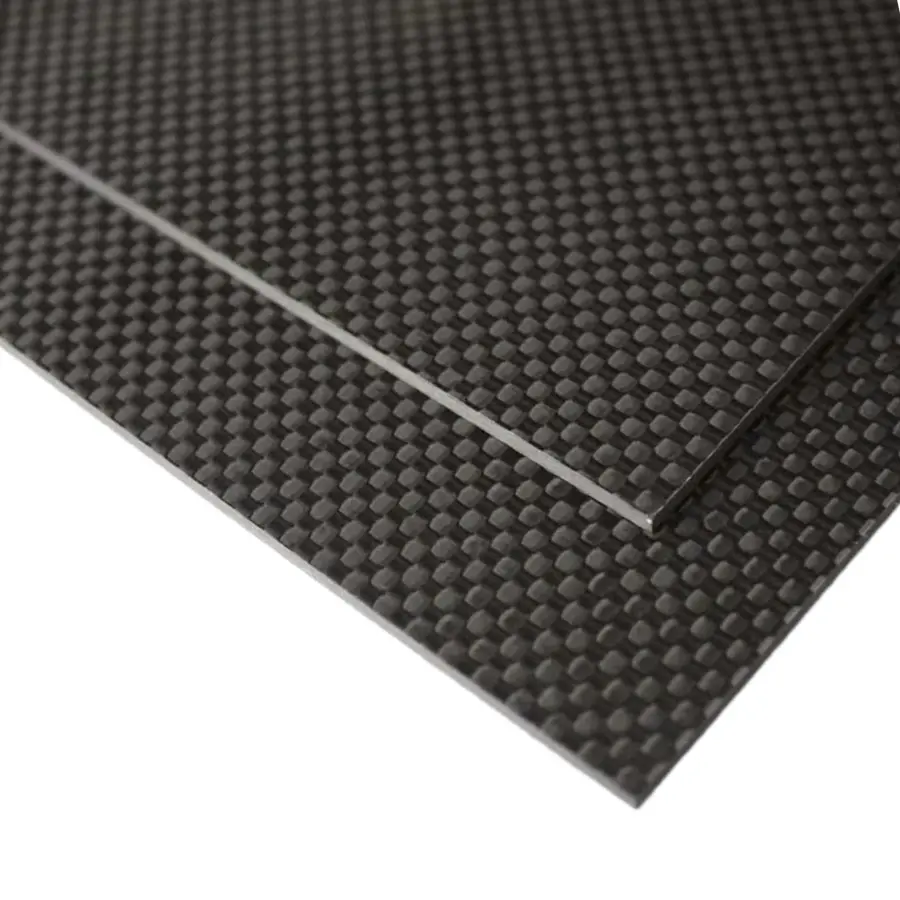

CFRP laminates are advanced composite materials composed of carbon fibers embedded within a polymer matrix. This unique combination results in a material that is both exceptionally strong and lightweight.

Manufacturing Process:

- Raw Material Selection: High-quality carbon fibers and resins, such as epoxy, are carefully selected based on the desired properties of the final product.

- Layup: Carbon fibers are layered in a specific orientation to achieve the required strength and stiffness properties.

- Curing: The layered composite is cured under controlled heat and pressure to bond the fibers and resin together, forming a solid laminate.

Properties and Benefits:

- High Strength-to-Weight Ratio: CFRP laminates offer superior strength and stiffness compared to traditional materials like metals, while maintaining a low weight.

- Corrosion Resistance: Resistant to a wide range of chemicals and environmental factors, making them ideal for harsh conditions.

- Dimensional Stability: Excellent dimensional stability, ensuring consistent performance over time.

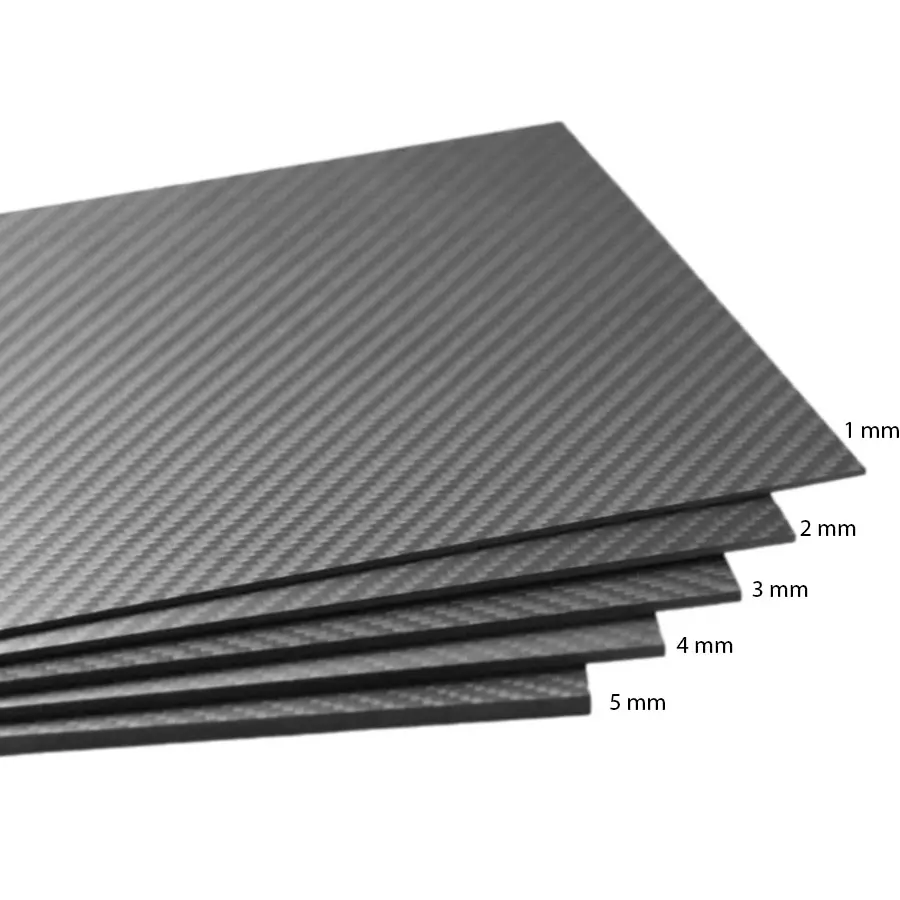

- Tailorability: The properties of CFRP laminates can be customized by varying the fiber orientation, resin type, and layer thickness.

Applications:

- Aerospace: Aircraft wings, fuselages, and interior components

- Automotive: High-performance vehicles, electric vehicle components

- Marine: Boat hulls, masts, and other marine structures

- Sports Equipment: Golf clubs, tennis rackets, bicycles

- Industrial Machinery: Robotic components, tooling

Technical Specifications:

- Tensile Strength: Typically ranges from 1500 to 2500 MPa

- Flexural Modulus: Typically ranges from 70 to 150 GPa

- Density: Approximately 1.5 g/cm³

Why Choose CFRP Laminates?

- Enhanced Performance: Achieve superior strength, stiffness, and weight savings.

- Durability: Resist damage from environmental factors and fatigue.

- Customization: Tailor the material to meet specific application requirements.

- Sustainability: Can contribute to more sustainable products and processes.

Conclusion CFRP laminates offer a unique combination of properties that make them a valuable material for a wide range of applications. Their high strength-to-weight ratio, corrosion resistance, and customizable nature make them an ideal choice for engineers and designers seeking to optimize the performance of their products

Office and Factory 1 address: Alley 1, Kieu Ky Street, Duong Xa Commune, Gia Lam District, Hanoi, Vietnam 100000

Factory 2 address: Tan Quang Commune, Van Lam District, Hung Yen Province, Vietnam 16000

Email: info@76plastic.com.vn

Phone number

Hotline: +84 243 6789 321

Mobile: Mr. Andy/+84 961 160 818 – Project Director

Fb: 76plastic

Reviews

There are no reviews yet.